SO2 Scrubber

Product Description

SO2 scrubbers are designed to trap sulphur dioxide emissions from manufacturing industries. Sulfur dioxide is a colorless and toxic gas, generated from the exhaust of coal-fired power plants and can be released into the atmosphere. As per the CPCB norms, the concentration of SO2 in the atmosphere should not be more than 80 µg/m3. In order to meet the acceptable ambient SO2 limit, the flue gas should be treated with scrubbing reagent before it releases into atmosphere.

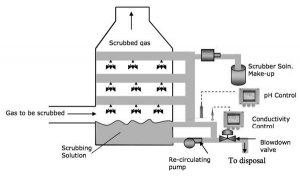

Scrubber works by spraying of chemical reagent and water into a chamber where the SO2 in exhaust gas reacts with absorbent to neutralize the pollutant and leaving the treated gas. Lime or limestone is being used as absorbent with water mix for many applications. Amount of SO2 generated, properties of gas, presence of other pollutants, temperature and CPCB norms at particular zone determine the selection of SO2 scrubber system and chemical agent.

Apzem has a well-built team of engineers and consultants with having thorough knowledge in designing of SO2 scrubber system for various chemical manufacturing industries, and helps to give better economical solution. Feel free to contact us for designing efficient and economically better scrubber to your specific process and pollution control requirements.

Technical Specification

- Air Flow: upto 70,000 CFM

- Efficiency : upto 99.99% capturing efficiency

- MOC: Mild Steel / SS 304 / SS316 / FRP / PP / PVC

- Finish: Powder coated / Matt finish

- Power option : 3 Phase.

- Customization : Yes , customization available suiting your needs.

Contaminants Removed

- H2S , HCl , HF , HBr

- HCN ,HNO3 , NH3

- Formic acid , Chromic acid

- SO2 , Cl2, F2, Br2 , BCl3, BF3

- Formaldehyde , Ethylene compounds

- Soluble alcohols, acids

- VOCs And many others

Applications

- Chemical Industries

- Petrochemical industries

- Oil Refineries

- Oil and gas extraction operations

- Food industries

- Pharmaceutical industries

- Power plants

- Sulfur product production

Advantage

- Can sustain highly corrosive atmosphere.

- Relatively low pressure drop.

- High mass transfer efficiency.

- Require relatively small space.

Other Technical Details

- Contaminant solubility

- Vapor pressures

- Wash liquid flow rate

- Liquid to gas ratio

- Packing chamber height, diameter, and volume

- Packing media type and size

- Chemical additives

- pH control

- Precipitation of reaction products

- Multiple solution scrubbing

- Required scrubbing stages

- Pressure drop across packing

- Materials of construction

- Site requirements

- Centrifugal Blower,

- Spiral Ducts,

- Flexible duct,

- Suction hoods,

- Magnahelic gauge,

- Packings

- PH meter

- Water Level indicator & controller

- Pump etc..

Certification : All Apzem Products are designed to comply with ACGIH and OSHA standards as well as local PCB Standards.

Warranty : All Apzem Products are minimum one year waranted for performance and quality.