Packed Bed Scrubber

Product Description

Technical Specification

- Air Flow: upto 70,000 CFM

- Efficiency : upto 99.99% capturing efficiency

- MOC: Mild Steel / SS 304 / SS316 / FRP / PP / PVC

- Finish: Powder coated / Matt finish

- Power option : 3 Phase.

- Customization : Yes , customization available suiting your needs.

Contaminants Removed

- H2S , HCl , HF , HBr

- HCN ,HNO3 , NH3

- Formic acid , Chromic acid

- SO2 , Cl2, F2, Br2 , BCl3, BF3

- Formaldehyde , Ethylene compounds

- Soluble alcohols, acids

- VOCs And many others

Applications

- Landfill and Biogas Contaminants

- Acid Fumes and gases

- Chemical Fumes and Odor

- Food Processing Odors

- Metal Finishing Fumes

- Steel Processing Fumes

- Wastewater treatment plant odors

Advantage

- Can sustain highly corrosive atmosphere.

- Relatively low pressure drop.

- High mass transfer efficiency.

- Require relatively small space.

Other Technical Details

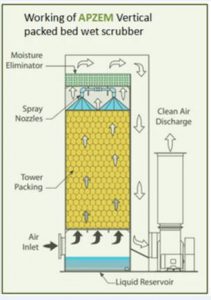

Vertical Packed Bed Scrubbers provide one of the most efficient removals of acid gases, odors and vapor fumes by using a vertical counter flow design. The contaminated gas flows up while recirculating liquid sprays downward into the packed bed. The gases are absorbed by the scrubber solution solubility level and by chemical reaction.

Vertical Packed Bed Scrubbers are commonly used in application removals of odors such as Amines, Ammonia, Diamines, H2S, Mercaptans, Organic Sulfides and Skatole.

The vertical counter-flow design typically provides the best scrubbing efficiency of vapors and is the most common design found in most industries. Vertical Packed Tower Scrubber is normally not used when solid particulate is in the air stream. Air flow capacity for a single shop fabricated tower can be up to 75,000 CFM.

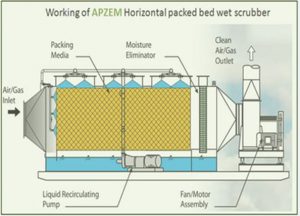

This is a cross-flow design with scrubbing liquid flowing vertically downwards while the gas passes horizontally through the packing section. Horizontal Packed Bed Scrubber is used when limited headroom is an issue at a customer’s facility or when low profile is desired for roof-top applications. Multiple stages can be easily provided in one housing with separate sumps and pumps if required.The cross-flow design is less susceptible to fouling for airstreams that may contain solid particulate. Air flow capacity for a single shop fabricated tower can be up to 75,000 CFM

- Contaminant solubility

- Vapor pressures

- Wash liquid flow rate

- Liquid to gas ratio

- Packing chamber height, diameter, and volume

- Packing media type and size

- Chemical additives

- pH control

- Precipitation of reaction products

- Multiple solution scrubbing

- Required scrubbing stages

- Pressure drop across packing

- Materials of construction

- Site requirements

- Centrifugal Blower,

- Spiral Ducts,

- Flexible duct,

- Suction hoods,

- Magnahelic gauge,

- Packings

- PH meter

- Water Level indicator & controller

- Pump etc..

Certification : All Apzem Products are designed to comply with ACGIH and OSHA standards as well as local PCB Standards.

Warranty : All Apzem Products are minimum one year waranted for performance and quality.