Marine Exhaust Gas Scrubber

Product Description

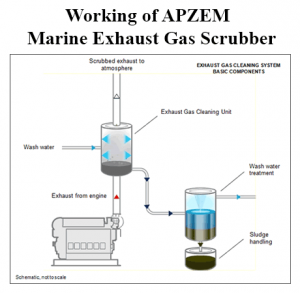

APZEM offers exhaust gas cleaning systems for marine industries. The marine exhaust gas cleaning scrubber system removes sulfur and harmful particulate matter (PM) from the ship. APZEM engineers have designed, customized, built for exhaust gas cleaning systems for SOx and particulate matter reduction as well as in controlling other pollutants and mists. It has industry-proven process technologies to help the organization, which has to reduce emissions, and help to enhance health and safety. The engineers design the marine scrubber as slim and reliable equipment on the market. This scrubber operates by spraying Caustic soda (NaOH) and seawater into the exhaust gas to trap the sulfur. APZEM marine scrubber enables to meet SOx limits without switching to expensive low sulfur fuel.

Based on the sources, marine scrubber can be designed for single exhaust emission source and multiple exhaust emission sources. It is classified into single stream inlet and multi steam inlet.

Technical Specification

- Air Flow: upto 70,000 CFM

- Efficiency : upto 99.99% capturing efficiency

- MOC: Mild Steel / SS 304 / SS316 / FRP / PP / PVC

- Finish: Powder coated / Matt finish

- Power option : 3 Phase.

- Customization : Yes , customization available suiting your needs.

Contaminants Removed

- H2S , HCl , HF , HBr

- HCN ,HNO3 , NH3

- Formic acid , Chromic acid

- SO2 , Cl2, F2, Br2 , BCl3, BF3

- Formaldehyde , Ethylene compounds

- Soluble alcohols, acids

- VOCs And many others

Features of marine scrubber:

- Allows the scrubber system to fit in existing funnel casing

- Reduces spaces and ducting requirements

- Scrubber meets back pressure requirements for the engine

- Low weight

- Minimal impacts on ship

- Adaptable design for installation

Advantage

Advantages of single stream inlet:

- Low installation costs

- Requires minimal changes to existing ductwork

- Optimizes each scrubber for dedicated exhaust source

- Fits in funnel where height is limited

Advantages of multi stream inlet:

- Fits where multiple smaller scrubbers do not if funnel space is limited

- Reduces number of installed scrubbers

- Reduces onboard auxiliary equipment

- May reduce system cost

Other Technical Details

Marine scrubber can be classified into following types based on the requirements and conditions.

Open loop system:

This system uses alkalinity of seawater as buffer with using fresh water. It is recommended to use open seas with moderate to high alkalinity.

Closed loop system:

This system works with using of minimal make up water and it uses additional reagent as buffer. It is recommended to apply water with low alkalinity such as ports, harbour, estuaries, canals and inland water ways.

Hybrid loop system:

It is a flexible design scrubber system and a combination of both open a closed loop. Since it applies to both conditions, with low alkalinity water and high alkalinity water, this type can be used for everywhere.

- Contaminant solubility

- Vapor pressures

- Wash liquid flow rate

- Liquid to gas ratio

- Packing chamber height, diameter, and volume

- Packing media type and size

- Chemical additives

- pH control

- Precipitation of reaction products

- Multiple solution scrubbing

- Required scrubbing stages

- Pressure drop across packing

- Materials of construction

- Site requirements

- Centrifugal Blower,

- Spiral Ducts,

- Flexible duct,

- Suction hoods,

- Magnahelic gauge,

- Packings

- PH meter

- Water Level indicator & controller

- Pump etc..

Certification : All Apzem Products are designed to comply with ACGIH and OSHA standards as well as local PCB Standards.

Warranty : All Apzem Products are minimum one year waranted for performance and quality.