Incinerator Scrubber

Product Description

Incineration is a waste treatment process that involves the combustion of organic substances contained in waste materials. Incineration of waste materials converts the waste into ash, flue gas, and heat.

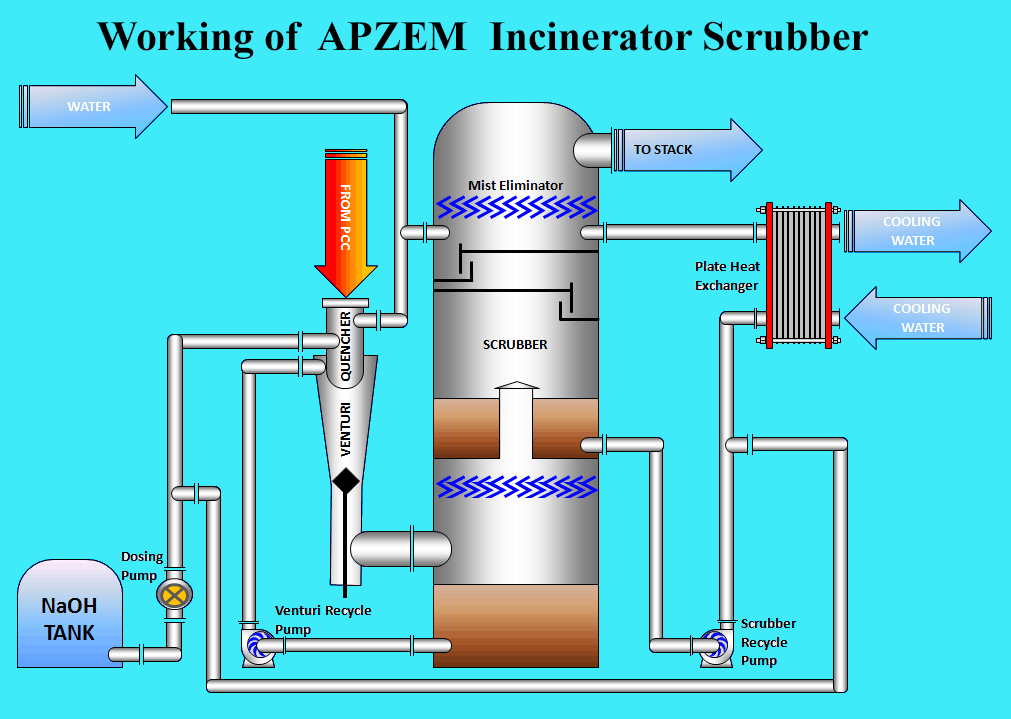

Incinerator Scrubber is used for the safe removal of harmful flue gases that are emitted from the incinerators and thermal oxidizers.

Incinerator scrubber is specially designed for high-temperature furnace and incinerator filter applications and for all combustion process that produces corrosive by-products.

Technical Specification

- Air Flow: upto 70,000 CFM

- Efficiency : upto 99.99% capturing efficiency

- MOC: Mild Steel / SS 304 / SS316 / FRP / PP / PVC

- Finish: Powder coated / Matt finish

- Power option : 3 Phase.

- Customization : Yes , customization available suiting your needs.

Contaminants Removed

- H2S , HCl , HF , HBr

- HCN ,HNO3 , NH3

- Formic acid , Chromic acid

- SO2 , Cl2, F2, Br2 , BCl3, BF3

- Formaldehyde , Ethylene compounds

- Soluble alcohols, acids

- VOCs And many others

Applied Industries

- Rotary kilns

- Calcinators

- Multiple hearth furnaces

- Refractory furnaces

- Fluidized bed furnaces

- Biomass grate furnaces

- Catalytic combustion furnaces

- Waste-fired boilers

- Liquid injection incinerators

- Direct flame gas incinerators

- Hazardous waste incinerators

- Sludge incinerators

- Fume oxidizers

- VOC oxidizers

Standard Features

- High efficiency packed bed incinerator scrubber

- Mist eliminator section – 99%+ efficient units available.

- Integral recirculation system and corrosion-resistant pump.

- Piping package for quench and scrubber sections.

- Vertical or horizontal wet quench section or quench venturi section.

- Instrumentation package, including pH control and flow sensors. Fully automated operation.

- Motor control starter package.

- Systems are custom-engineered to accommodate user gas volume and contaminant input/output loading.

Other Technical Details

Customization Factors

Accessories

Others

Customization Factors

- Contaminant solubility

- Vapor pressures

- Wash liquid flow rate

- Liquid to gas ratio

- Packing chamber height, diameter, and volume

- Packing media type and size

- Chemical additives

- pH control

- Precipitation of reaction products

- Multiple solution scrubbing

- Required scrubbing stages

- Pressure drop across packing

- Materials of construction

- Site requirements

Accessories

- Centrifugal Blower,

- Spiral Ducts,

- Flexible duct,

- Suction hoods,

- Bio media etc…

Others

Certification : All Apzem Products are designed to comply with ACGIH and OSHA standards as well as local PCB Standards.

Warranty : All Apzem Products are minimum one year waranted for performance and quality.