Inert Gas Scrubber

Product Description

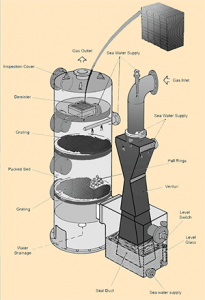

Hence these gases are thoroughly washed with seawater which is freely available in abundance in the proximity of the ship. The process consists of having a large tall structure known as the scrubber. There is an isolating valve between the boiler uptake and the scrubber tower which serves to isolate the two portions when required for purposes of maintenance.

Sea water flows downwards in the scrubber while the flue gases rise upwards and during this process of cross-flow the sea water dissolves the soot and sulphur dioxide as well as cools the gas. There is an extensive arrangement of spray nozzles, perforated plates and venture nozzles inside the tower to maximize the contact between the water and gases. Therefore it acts like a heat exchanger and the exact design of the scrubber tower could vary depending on the make of the machine and the intended purpose of use.

The working conditions require that the scrubber is made out of highly corrosion resistant material which can withstand the hot corrosive gases that pass through it and there should be ample provision for viewing and cleaning the inside portions of the chamber during maintenance routine.

After the scrubber the gas passes through a demister which removes excess of water from the flue gases which is done using materials such as polypropylene or cyclone dryers. This gas is now ready to be sent to inert gas blowers which pump this gas further to the required regions.

Apart from being used in inert gas systems, scrubbers would become compulsory in ships in the coming days once relevant IMO regulations take effect.

Technical Specification

- Air Flow: upto 70,000 CFM

- Efficiency : upto 99.99% capturing efficiency

- MOC: Mild Steel / SS 304 / SS316 / FRP / PP / PVC

- Finish: Powder coated / Matt finish

- Power option : 3 Phase.

- Customization : Yes , customization available suiting your needs.

Contaminants Removed

- H2S , HCl , HF , HBr

- HCN ,HNO3 , NH3

- Formic acid , Chromic acid

- SO2 , Cl2, F2, Br2 , BCl3, BF3

- Formaldehyde , Ethylene compounds

- Soluble alcohols, acids

- VOCs And many others

Applications

- Landfill and Biogas Contaminants

- Acid Fumes and gases

- Chemical Fumes and Odor

- Food Processing Odors

- Metal Finishing Fumes

- Steel Processing Fumes

- Wastewater treatment plant odors

Advantage

- Can sustain highly corrosive atmosphere.

- Relatively low pressure drop.

- High mass transfer efficiency.

- Require relatively small space.

Other Technical Details

- Contaminant solubility

- Vapor pressures

- Wash liquid flow rate

- Liquid to gas ratio

- Packing chamber height, diameter, and volume

- Packing media type and size

- Chemical additives

- pH control

- Precipitation of reaction products

- Multiple solution scrubbing

- Required scrubbing stages

- Pressure drop across packing

- Materials of construction

- Site requirements

- Centrifugal Blower,

- Spiral Ducts,

- Flexible duct,

- Suction hoods,

- Magnahelic gauge,

- Packings

- PH meter

- Water Level indicator & controller

- Pump etc..

Certification : All Apzem Products are designed to comply with ACGIH and OSHA standards as well as local PCB Standards.

Warranty : All Apzem Products are minimum one year waranted for performance and quality.