Ammonia Gas Scrubber

Product Description

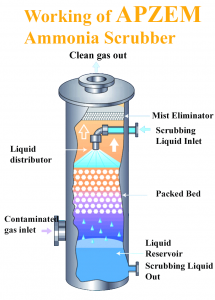

Wet scrubbers remove pollutants by injecting liquid into the gas stream. In scrubbers that are designed to remove particulates (such as dust scrubbers), the particulate is captured by the water droplets before it is discharged through the exhaust stack. Chemical scrubbers are different; the liquid in question causes a chemical reaction that strips the chemical pollutant out of the waste stream. Manufacturers in the chemical industry are required by law to reduce or eliminate their ammonia gas emissions. Turn to Pollution Systems for reliable, top-quality ammonia scrubbers like Apzem Ammonia removal scrubber will provide outstanding performance with minimal maintenance.

In the case of ammonia scrubbers, dilute sulfuric acid is typically used to neutralize the ammonia. The resulting byproduct, a form of salt, is collected and removed through the wastewater blow down, as the treated air stream is exhausted through the stack.

Efficiency is critical for ammonia scrubbers. Due to its toxicity, ammonia gas is a regulated compound that needs to be treated below established limits before it is released into the atmosphere.

Technical Specification

- Air Flow: upto 70,000 CFM

- Efficiency : upto 99.99% capturing efficiency

- MOC: Mild Steel / SS 304 / SS316 / FRP / PP / PVC

- Finish: Powder coated / Matt finish

- Power option : 3 Phase.

- Customization : Yes , customization available suiting your needs.

Contaminants Removed

- H2S , HCl , HF , HBr

- HCN ,HNO3 , NH3

- Formic acid , Chromic acid

- SO2 , Cl2, F2, Br2 , BCl3, BF3

- Formaldehyde , Ethylene compounds

- Soluble alcohols, acids

- VOCs And many others

Advantage

- Can sustain highly corrosive atmosphere.

- Relatively low pressure drop.

- High mass transfer efficiency.

- Require relatively small space.

Other Technical Details

- The presence of other chemicals or particulates in the exhaust stream

- The temperature and flow rate of the waste stream

- The initial concentration of the ammonia in the waste stream

- Contaminant solubility

- Vapor pressures

- Wash liquid flow rate

- Liquid to gas ratio

- Packing chamber height, diameter, and volume

- Packing media type and size

- Chemical additives

- pH control

- Precipitation of reaction products

- Multiple solution scrubbing

- Required scrubbing stages

- Pressure drop across packing

- Materials of construction

- Site requirements

- Centrifugal Blower,

- Spiral Ducts,

- Flexible duct,

- Suction hoods,

- Magnahelic gauge,

- Packings

- PH meter

- Water Level indicator & controller

- Pump etc..

Certification : All Apzem Products are designed to comply with ACGIH and OSHA standards as well as local PCB Standards.

Warranty : All Apzem Products are minimum one year waranted for performance and quality.